Cryogenic Nitrogen Generator

JYH Big Engineering & Consultants brings the best Cryogenic Nitrogen Plants offered capacities range from 50 Nm3/hr to 5000 Nm3/hr.

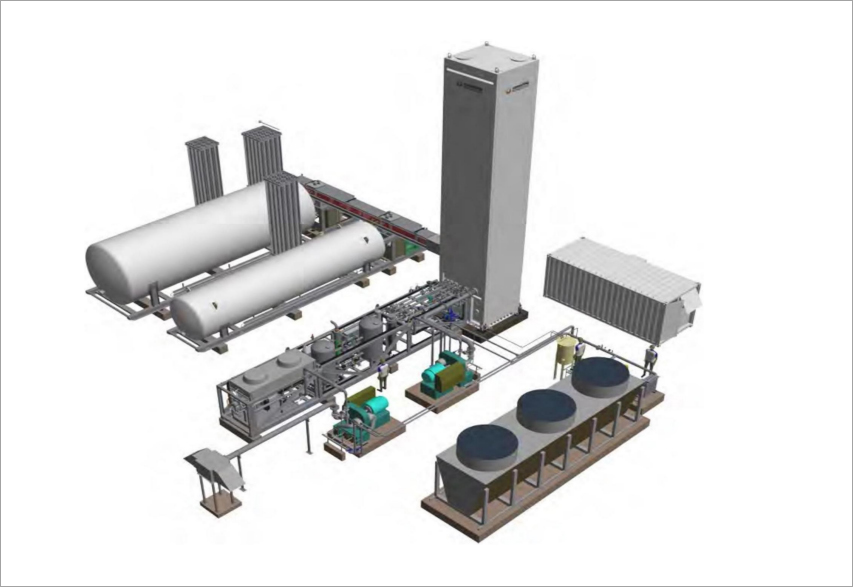

HOW IT WORKS

Liquid Nitrogen plant's operating principle that is based on fractional distillation to enable the production of nitrogen with high purity. The atmospheric air is sucked up by an air compressor is taken into the air purification system where the impurities like hydrocarbons, moisture as well as carbon dioxide, are eliminated. The air then passes through heat exchangers, where it is then cooled down to the cryogenic temperature. Then, nitrogen is pumped into the distillation column , where the nitrogen gas is separated physically from all other gases and located on the upper part in the column. The nitrogen is then removed from the column and transferred to a low pressure columns where it is distilled until it is in compliance with commercial standards for purity.We are top manufacturer of Cryogenic Nitrogen Generator , Contac us if you urgent need.

Applications of Liquid Nitrogen :

Serves as coolant for computers and vacuum pump systems

Cooling of superconductors

Storage of foods for food preservation

Cryopreservation of blood

Cryosurgery for removing dead cells from brain

Preservation of semen of animals

Working substance for liquid nitrogen power vehicle and much more

Cryo treatment of various metals to improve the properties

Cylinder filling for commercial use