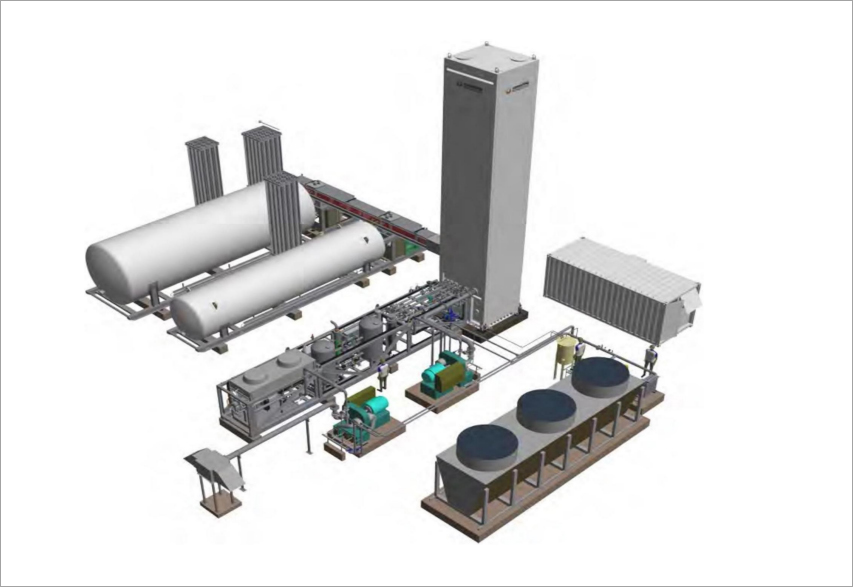

Cryogenic Oxygen Plants

JYH Big Engineering & Consultants offers the top Cryogenic Oxygen Plants offered capacities vary from 50 Nm3/hr up to 5500 Nm3/hr.

HOW IT WORKS

Cryogenic Oxygen Plants working principle is based on fractional distillation, which allows for the creation of high purity oxygen. The atmospheric air is sucked up through an air compressor, and then pumped into an air purification unit. There, contaminants like hydrocarbons, moisture, and carbon dioxide get eliminated. After that, the air passes through heat exchangers and is chilled to the cryogenic temperature. This is the point at which Oxygen is pumped into the distillation columns where Oxygen is physically isolated from other gases and is created on the floor of the column with (-) temperature of 185 degrees Celsius.

Applications of Cryogenic Oxygen Plants :

Our Liquid Oxygen plants are widely used in the following applications

Hospitals as a backup of Oxygen cylinders

Paper & Pulp industry for Oxy bleaching

Glass industry

Metallurgical industry

Furnaces for oxygen enrichment

Fish farming etc.